The main advantages of diesel screw air compressors include high efficiency and energy saving, smooth operation, low noise, easy maintenance and a wide range of applications. These advantages make diesel screw air compressors outstanding in a variety of industrial applications.

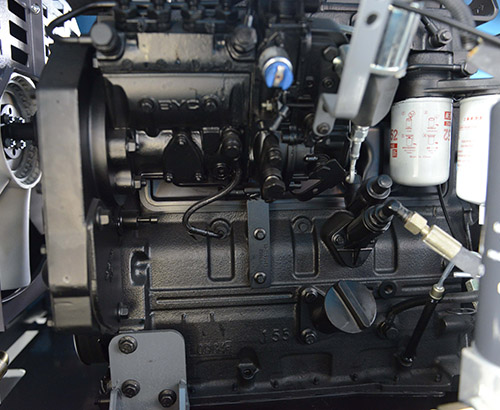

1.First of all, diesel screw air compressor in the compression process, because the gap between the screw and the screw and the shell is very small, the leakage of gas is greatly reduced, thus improving the compression efficiency.

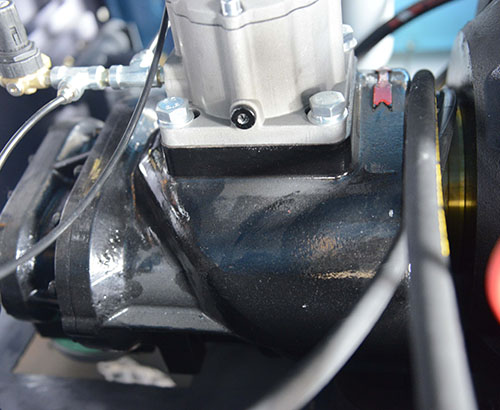

2.Secondly, the operation of diesel screw air compressor is stable and the noise is low. Because the rotating movement of the screw is continuous, and the speed is relatively stable, the vibration and noise generated are relatively small. In addition, diesel screw air compressors usually use low noise design, such as the installation of silencers, the use of sound insulation materials, etc., to further reduce the operating noise.

3.Finally, the maintenance of diesel screw air compressors is also relatively convenient. Its structure is relatively simple, the number of parts is small, and it is easy to disassemble and replace. This makes daily maintenance easier and faster. At the same time, diesel screw air compressor is made of high-quality materials and precision machining technology, with high wear resistance and corrosion resistance, and can run stably for a long time in harsh working environments

| Model Number | ZD-29/25 |

| Power Source | Diesel |

| Configuration | Mobile |

| Place of Origin | China |

| Dimension(L*W*H) | 3100*1900*1950mm |

| Weight | 3300kg |

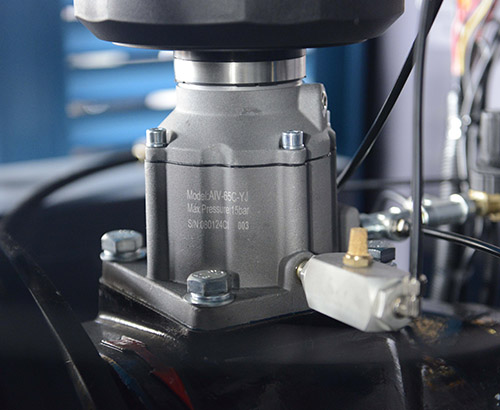

| Working Pressure | 25 bar |

| Air capacity | 29m³/min |

| Cooling method | Air Cooled |

| Fuel tank capacity -G1″ |

230L |

| average fuel consumption | 65-75L |

| Noise | 85dB |

| Speed | 1420rpm |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Application | Mining,Construction |