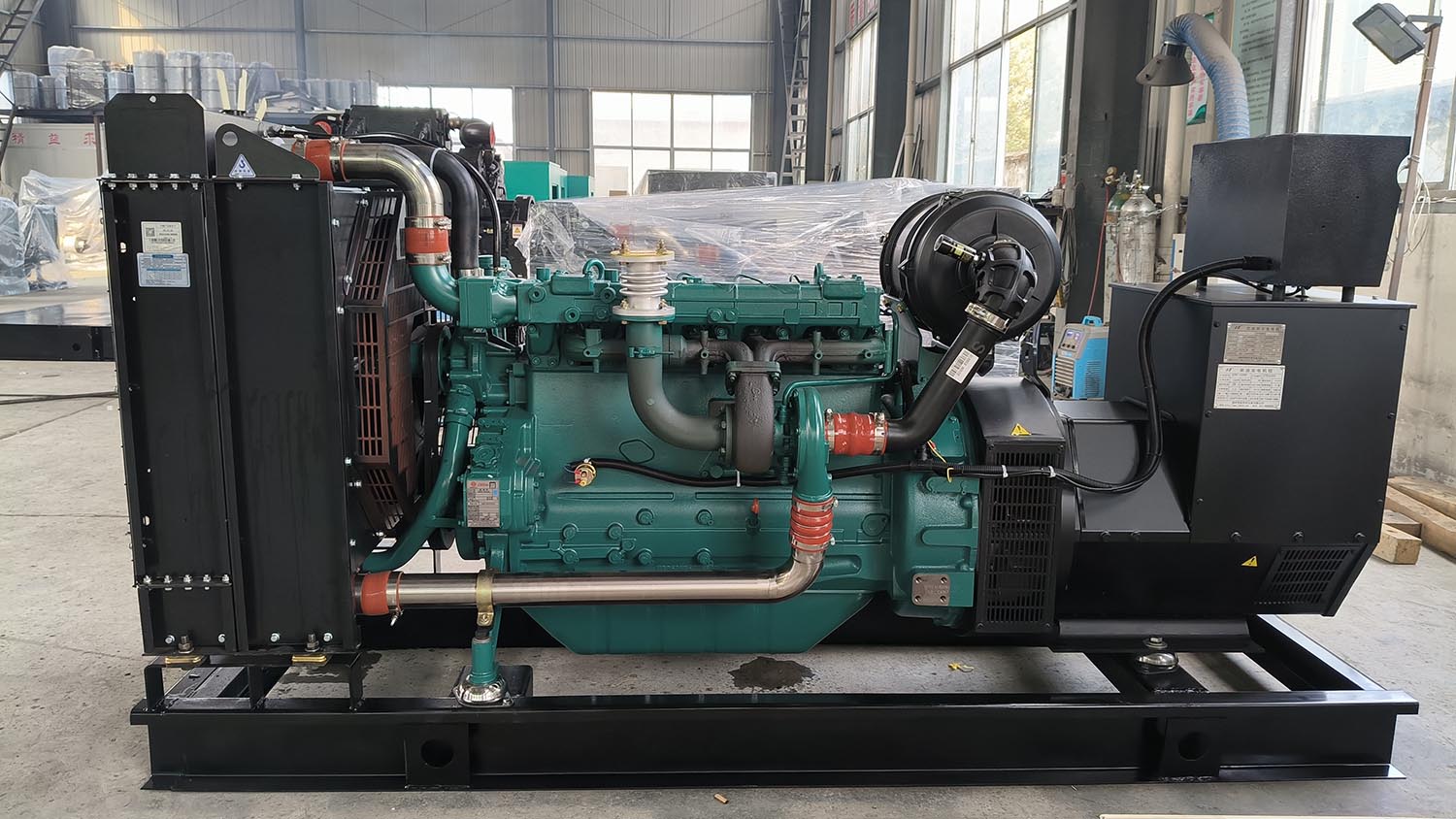

Diesel generators are important backup power equipment. Regular care and maintenance can ensure their long-term stable operation and extend their service life. The following will introduce the maintenance methods of diesel generators to help you better manage and maintain your generator.

1. Change engine oil and oil filter regularly: Engine oil is necessary for normal engine operation. It lubricates and cools the moving parts inside the engine. Engine oil and oil filter need to be changed regularly to keep the engine in good working order. According to the owner’s manual, it is recommended to change the oil and oil filter every 100-300 hours or every 3 months.

2. Clean the air filter: The air filter filters contaminants and dust from the air that enters the interior of the engine. Check and clean the air filter regularly to ensure it remains in good working order. It is recommended to inspect and clean every 100-300 hours or every 3 months.

3. Check the cooling system: The cooling system of a diesel engine cools the engine. Coolant levels and quality need to be checked regularly. If necessary, add an appropriate amount of coolant or replace the coolant. At the same time, make sure there are no leaks or blockages in components such as water pumps, water pipes, and radiators in the cooling system.

4. Check the fuel system: The smooth operation of the fuel system is critical to the engine. Check the fuel filter and fuel lines regularly to make sure they are free of dirt and blockage. Replace the fuel filter as needed, and be sure to use high-quality diesel fuel to prevent a clogged fuel filter that could cause the engine to stop running.

5. Regular cleaning: Clean the casing and radiator of the generator set regularly to prevent the accumulation of dust and debris. Make sure there is good ventilation and no obstructions around the generator.

6. Start-up and load testing: Start the generator regularly and connect a load to its output to simulate actual usage scenarios. This ensures that the generator is working properly and meeting power needs.

7. Anti-corrosion protection: In humid or corrosive environments, use appropriate anti-corrosion materials to protect the generator casing and connecting parts. Regularly inspect and repair the anti-corrosion measures of the generator set.

8. Check electrical connections regularly: Check that the cables and connections of the generator set are tight. Make sure electrical ground connections are good and inspect wires and cables for wear or age.

9. Maintenance records and maintenance plans: Establish maintenance records and maintenance plans, and accurately record the time and content of each maintenance. This helps track maintenance on the generator set and provides a reference for future maintenance.

At the same time, please pay attention to the following safety precautions:

– Before any maintenance work, cut off the power supply and ensure that it is in a safe condition.

– Operate equipment according to manufacturer’s instructions and safe operating procedures.

– If you do not have the relevant skills and knowledge, it is best to consult professionals who can conduct professional analysis and provide accurate suggestions and solutions based on your specific needs.